Not known Details About Lean Manufacturing s

Wiki Article

Examine This Report about Additive Manufacturing

Table of ContentsThe Only Guide to Hon Hai PrecisionThe Single Strategy To Use For Plastic ManufacturingThe Definitive Guide for Manufacturing Industries10 Simple Techniques For OemFacts About Lean Manufacturing RevealedThe Ultimate Guide To Lean Manufacturing

The text on this web page is an example from our full White Paper 'Shot Moulding for Purchasers' - * Example text * - for full overview click the download button over! Intro This overview is planned for individuals who are seeking to source plastic mouldings. It gives a much needed understanding right into all that is involved with developing plastic parts, from the mould device required to the moulding process itself.If you intend to explore even more, the overview covers sorts of mould tools, as well as unique ending up procedures such as colours & plating. Words that are underlined can be found in the reference in the appendix ... Component I: Moulding: The Basics The Advantages of Injection Moulding Plastic injection moulding is a very exact procedure that supplies numerous benefits over other plastic handling methods.

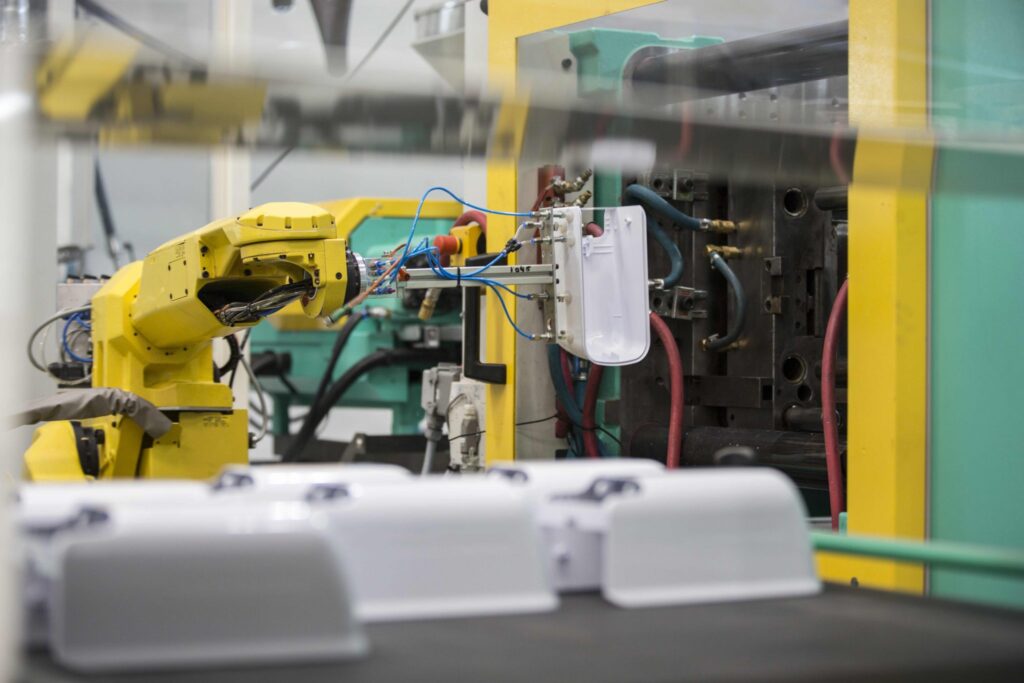

Accuracy is best for extremely detailed components. Compared to other strategies, moulding permits you to include more features at really little resistances. Have a look at the image to the. You can hold this moulding in the palm of your hand as well as it has employers, ribs, metal inserts, side cores as well as holes, made with a gliding closed off attribute in the mould tool.

Some Known Questions About Manufacturing.

Rumored Buzz on Lean Manufacturing

from material feed & melting; material injectionProduct cooling time and ejection to the re-closing of the mould tool ready device the next cycle. Draft angles - The wall surfaces of a moulded part ought to be a little tapered in the direction in which the component is ejected from the mould tool, to enable the component to be expelled conveniently.Ejector stroke - The pressing out of ejector pins to eject the moulded component from the mould tool. Ejector stroke speed, size as well as timing needs to be meticulously managed to stop damage to the ejectors and mould tool, however at the very same time make the moulding cycle as short as feasible.

The smart Trick of Lean Manufacturing That Nobody is Discussing

Ribs - When a plastic part has thin walls, ribs are included in the layout to make the slim wall surfaces more powerful Side cores - Side action a knockout post which produces an attribute on a moulded component, at an opposing angle to the regular opening instructions of the mould tool. oem. The side core requires to be able to retract as the plastic part can not be expelled or else.

Wall surfaces - The sides of a moulded component The text on this page is an example from our full White Paper 'Shot Moulding for Buyers'.

Production procedure for creating components by injecting liquified product right into a mould, or mold and mildew Simplified diagram of the procedure Injection moulding (united state punctuation: injection molding) is a manufacturing procedure for producing parts by infusing molten material into a mould, or mold and mildew. Injection moulding can be performed with a host of materials generally consisting of steels (for which the process is called die-casting), glasses, elastomers, confections, and also most typically polycarbonate and also thermosetting polymers. Shot moulding is commonly utilized for making a variety of components, from the tiniest parts to whole body panels of cars and trucks. Breakthroughs in 3D printing Check This Out modern technology, using photopolymers that do not melt during the injection moulding of some lower-temperature thermoplastics, can be used for some straightforward shot moulds. Shot moulding utilizes a special-purpose device that has three components: the shot unit, the mould as well as the clamp.

The Plastic Manufacturing PDFs

Process attributes [modify] Shot moulding utilizes a ram or screw-type bettor to compel molten plastic or rubber product right into a mould dental caries; this solidifies into a shape that has adapted the shape of the mould. It is most generally utilized to process both polycarbonate and thermosetting polymers, with the volume utilized of the previous being substantially higher.: 13 Thermoplastics are widespread due to characteristics that make them extremely suitable for shot moulding, such as convenience of recycling, convenience for a wide array of applications,: 89 and also capability to soften and also flow on heating.In multiple cavity moulds, each dental caries can be identical and also form the exact same components or can be unique and form numerous various geometries during a solitary cycle. Moulds are normally made from tool steels, yet stainless-steels and also aluminium moulds are ideal for specific applications. Aluminium moulds are commonly improper for high quantity manufacturing or get rid of narrow dimensional resistances, as they have substandard mechanical buildings and also are more prone to use, damages, and contortion throughout the injection as well as securing cycles; nonetheless, aluminium moulds are affordable in low-volume applications, as mould construction expenses as well as time are considerably reduced.

When sufficient material has gathered, the product is required at high pressure Related Site as well as speed right into the component forming tooth cavity. The specific amount of shrinkage is a feature of the material being utilized, as well as can be fairly predictable. To stop spikes in pressure, the process typically utilizes a transfer position matching to a 9598% complete tooth cavity where the screw changes from a continuous rate to a consistent pressure control.

What Does Manufacturing Industries Do?

The packaging stress is applied up until the gateway (cavity entryway) strengthens. Due to its little size, the gate is typically the first area to strengthen with its whole thickness.: 16 Once the gateway strengthens, no more material can enter the tooth cavity; accordingly, the screw reciprocates and obtains product for the following cycle while the material within the mould cools down so that it can be expelled and also be dimensionally secure.Report this wiki page